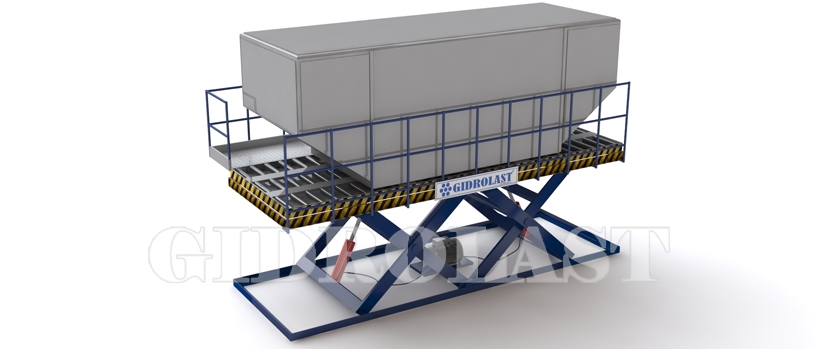

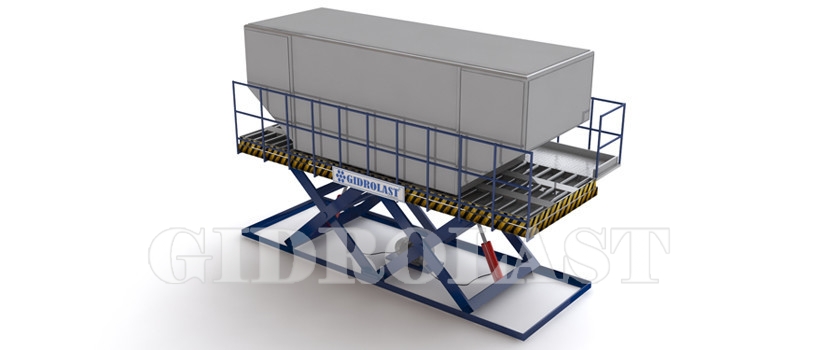

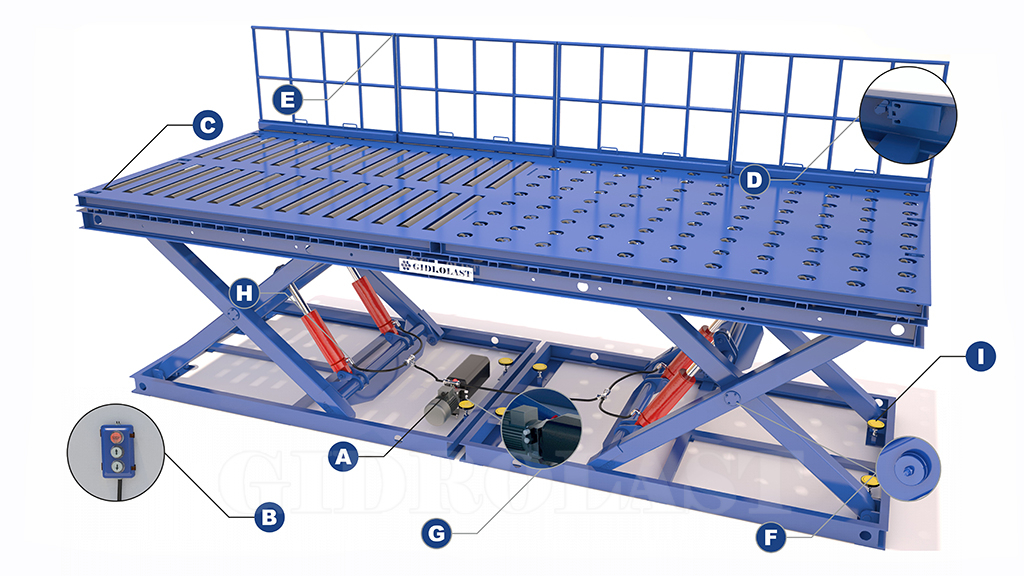

Air cargo heavy duty scissors lift

E-mail: sale@gidrolast.com

International sales team

Technical specifications

| Capacity:to 7000kg (15.500lb); |

| Dimensions of table:3600 х 2700mm (140"x 100"); |

| Max.lifting height:to 6000mm (240") |

| Min.height of the platform:from 300 mm (12"); |

| Operating temperature:from -20° С to +50° С, (-4°F...to 122°F); |

| Explosion protection ATEX rated:are available; |

Description

Because of its premium features and ability to provide up to five times the number of cycles as competing brands, the air cargo heavy-duty scissors lift has become the standard for the logistics and aerospace industries. Premium features included on these air container dock lifts include captured rollers, two-piece self-aligning cylinder, one-piece axle pins and high impact spiral wound bearings – all of which combine to give our customers the most rigid, robust and longest-lasting dock scissors lift available.

Product details

- A. Built-in hydro-electric station, 24 V, 1.1 kW.

- B. Remote control panel.

- C. A rolling platform that facilitates the rolling of containers without the need for additional lifting devices.

- D. Limit switches for limiting the lifting height and shutting down the hydraulic station after lowering.

- E. Fencing of the lifting platform on one side.

- F. Press – oilers (greases) for service maintenance of all mobile units of the lifting mechanism.

- G. Chokes for adjusting the lifting and lowering speed of the lifting table.

- H. Safety valves (preventing the table from falling in case of pressure loss in the hydraulic system).

- I. Mechanical movement stops in the folded state.

- All scissors rollers are captured within structural steel channels to provide excellent load stability.

- High impact, spiral wound bearings at every pivot point provide maintenance-free, rugged resistance to abrasion, impact and uneven loads.

- Structural cross-members at every pinned joint in the scissors assembly minimises leg deflection due to twisting or spreading under high/uneven loading.

- All hydraulic cylinders contain two-piece, self-aligning piston rods that transmit minimal side forces to the cylinder hinges/pins, significantly reducing wear.

- Structural steel channels in all upper and lower frames provide additional rigidity and resistance to twisting and bending of the lift under load.

- Tubular steel legs and added stiffeners provide overall stability and straight, repeatable tracking of the rollers as the lift raises and lowers.

- Joints, the most critical wear points in the lift, feature chrome-plated, 100,000 psi, ultimate-strength pins for premium load strength and long life.

Why choose our company?

Quote solutions

Do not hesitate to contact our international sales team, located in Milan, ITALY, who are at your disposal for all commercial and technical requests or any other inquiry.

For your information, Gidrolast is seeking foreign distributors to publicise our Company and sell our products.

If you want advanced technical information, send us the following form and we will get back to you as soon as possible.

just scan the barcode.

Quote solutions

Do not hesitate to contact our international sales team, located in Milan, ITALY, who are at your disposal for all commercial and technical requests or any other inquiry.

For your information, Gidrolast is seeking foreign distributors to publicise our Company and sell our products.

If you want advanced technical information, send us the following form and we will get back to you as soon as possible.

Online request

Photo presentation