Stationary rigging systems

E-mail: sale@gidrolast.com

International sales team

Technical specifications

| Maximum lift height:12 meters (40ft); |

| Maximum load capacity:from 12t (26.500lb) to 1 000t (2.200k lb); |

| Rate of ascent / descent under load:20 mm/s; |

| Speed of horizontal movement:7 mm/s; |

| Maximum pressure on the working surface:and 5 N/cm2; |

| Voltage:380/440 Vac, 50/60 Hz; |

Description

Answering the demands of the market, Gidrolast has developed and manufactured a complete range of advanced hydraulic gantry crane. They are designed to handle loads up to a thousand tons. All our gantries are delivered with specific properties and control systems to ensure optimum stability and safety.

Gidrolast stationary hydraulic gantry systems have a number of unique features: self-contained hydraulic systems, GidrolastSafe, wireless control systems and high grade steel technology. GidrolastSafe ensures safety – it is the safest possible method to operate a gantry. This wireless control system provides the operator with information about the stroke, lift and load per unit. And it automatically corrects any unsynchronised motion of the individual units.

All equipment will be painted in your corporate colours.

This system will be certified by Lloyds by means of a functional overload test at 120% of the maximum working load.

100% guarantee for 12 months after delivery.

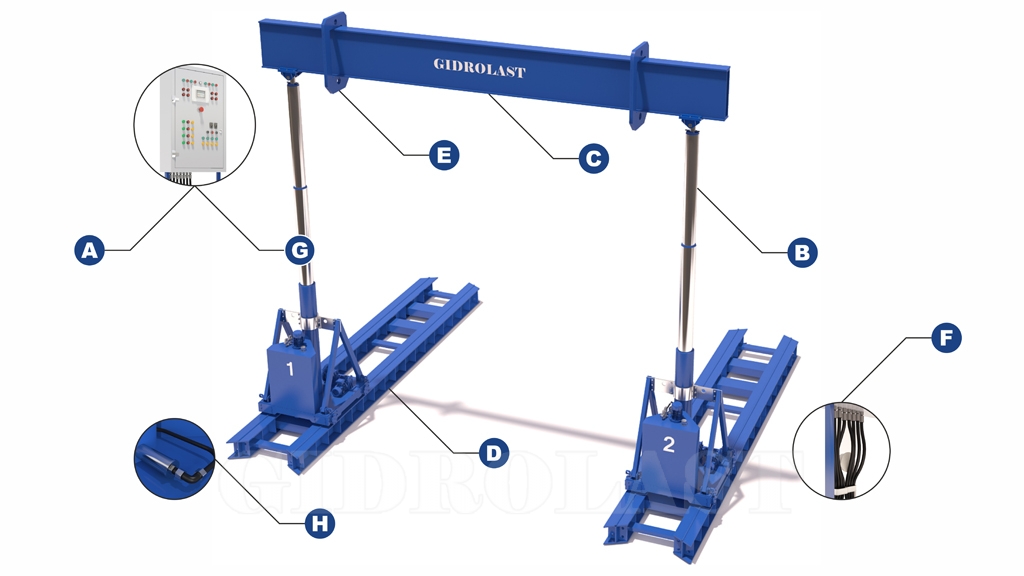

Product details

- A. A. Control cabinet. Hydraulic locking system. Hydraulic power pack is contained in the unit.

- B. Telescopic system consisting in 2 or 4 rack lifts. Two- or three-stage fully powered hydraulic cylinders. Self-propelled wheels.

- C. Upper support beam made with the following sizes: 6, 8 and 10 meters, number of beams in the delivery set is 2 pcs. For a four-rack system and 1 beam for a two-rack complex. Octagonal beam design.

- D. Block rails are supplied 3 meters long, and are installed on both sides of the longitudinal lift line, under each rack. Block rails are interconnected by bolted connection.

- E. Roller blocks of lateral displacement are installed in pairs on each beam; Optionally equipped with synchronous drive.

- F. Connection cables and wires – 1 set.

- G. Software – 1 set.

- H. Safety Valves. GidrolastSafe control system.

- I. A set of specialized tools required for dismantling/mounting the system.

- J. Seal kit. As well as spare parts for tools and accessories.

Why choose our company?

Quote solutions

Do not hesitate to contact our international sales team, located in Milan, ITALY who are at your disposal for all commercial and technical requests or any other inquiry.

For your information, Gidrolast is seeking foreign distributors to publicise our Company and sell our products.

If you want advanced technical information, send us the following form and we will get back to you as soon as possible.

just scan the barcode.

Quote solutions

Do not hesitate to contact our international sales team, located in Milan, ITALY who are at your disposal for all commercial and technical requests or any other inquiry.

For your information, Gidrolast is seeking foreign distributors to publicise our Company and sell our products.

If you want advanced technical information, send us the following form and we will get back to you as soon as possible.

Online request

Photo presentation